IPT’s Laboratory for Corrosion and Protection gives supports to the productive sector through technological services. Additionally, the Lab offers applied research for solving specific technological challenges. The laboratory has already developed about 140 research and development projects to almost all industrial sectors including: communication; automobile industries (mainly in developing cars moved by ethanol); metallurgical industries; electrical energy (production, transmission and distribution); basic sanitation and oil and gas sector. Currently, there are 24 research projects in development.

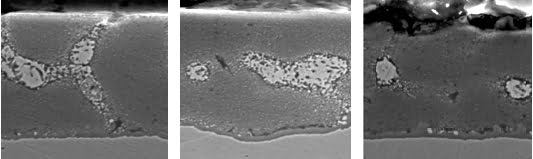

For the automobile sector, the Lab had an effective participation in the Pro-alcohol program, selecting and identifying metallic coatings applied on parts made of die cast alloys.

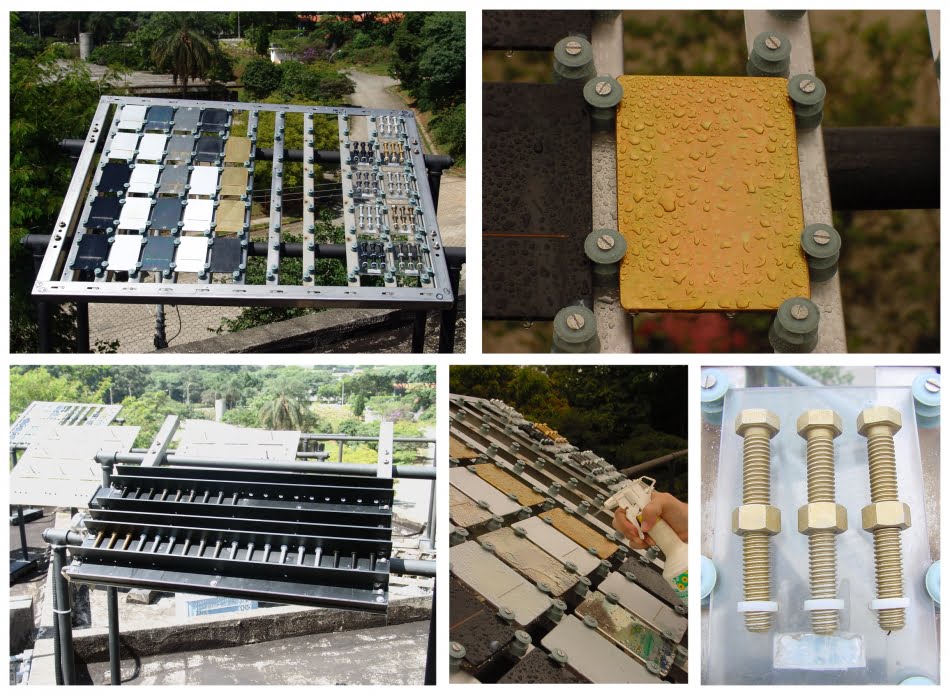

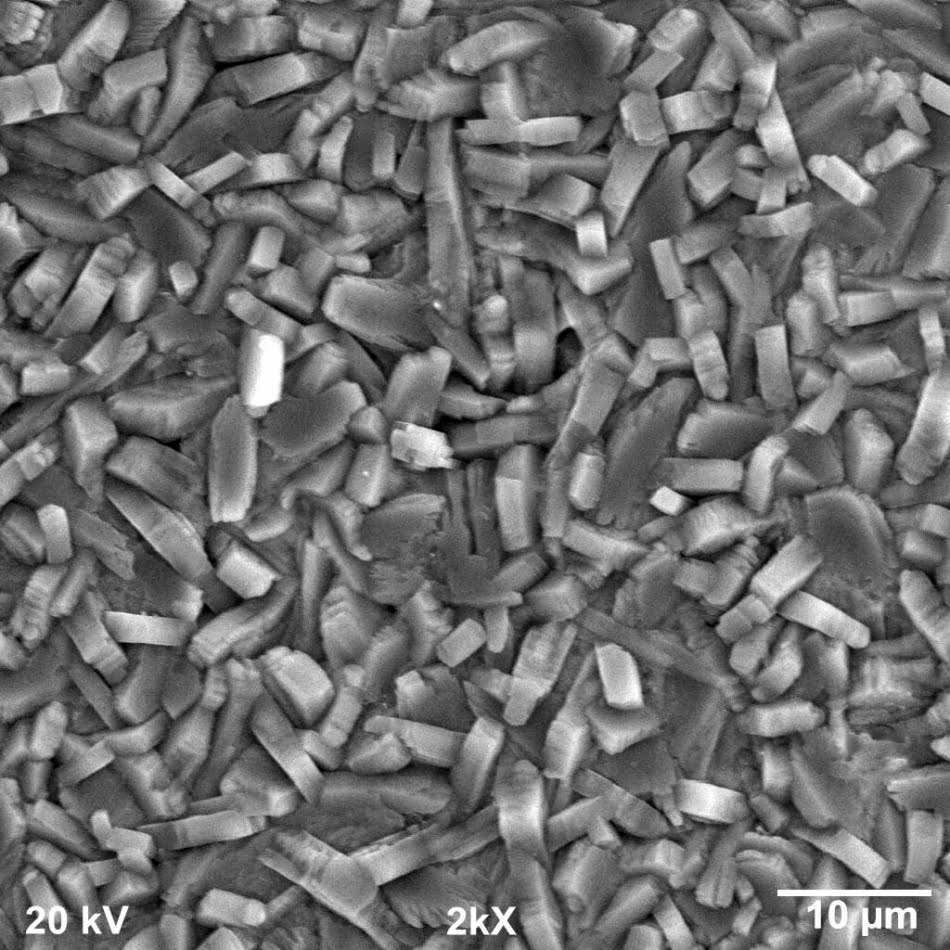

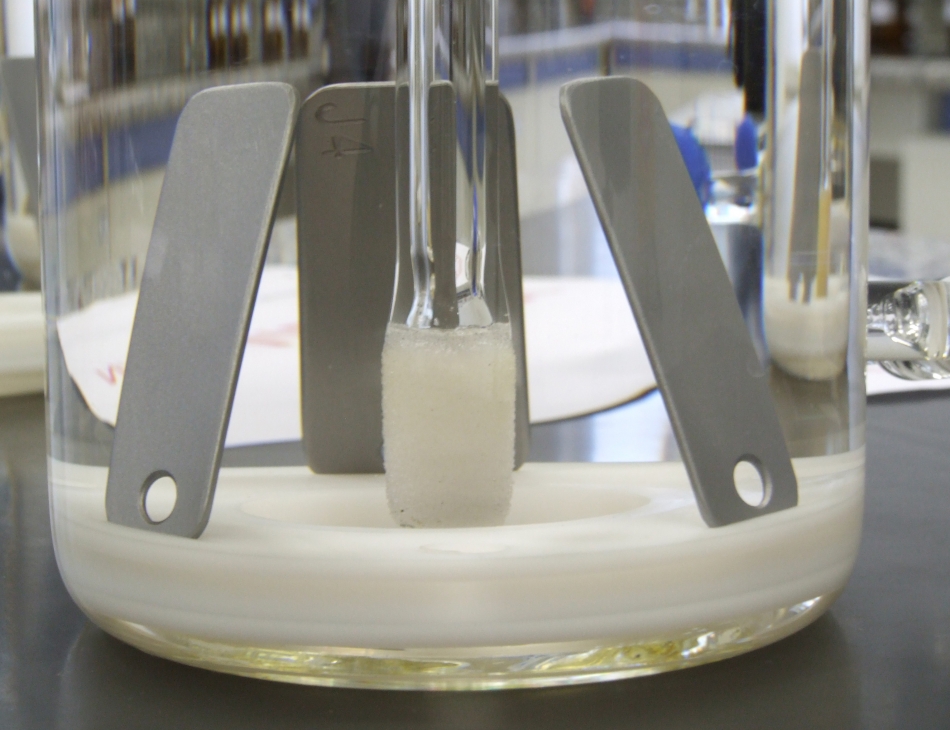

For the metallurgical sector, the Lab developed projects related to electroplating of metals; phosphating of steel coils for forming; continuous hot-dip galvanizing for wires; steel wire coppering using electroless copper plating; black chrome electroplating for solar absorbers as well as developing studies related to the measuring of industrial atmosphere corrosivity.

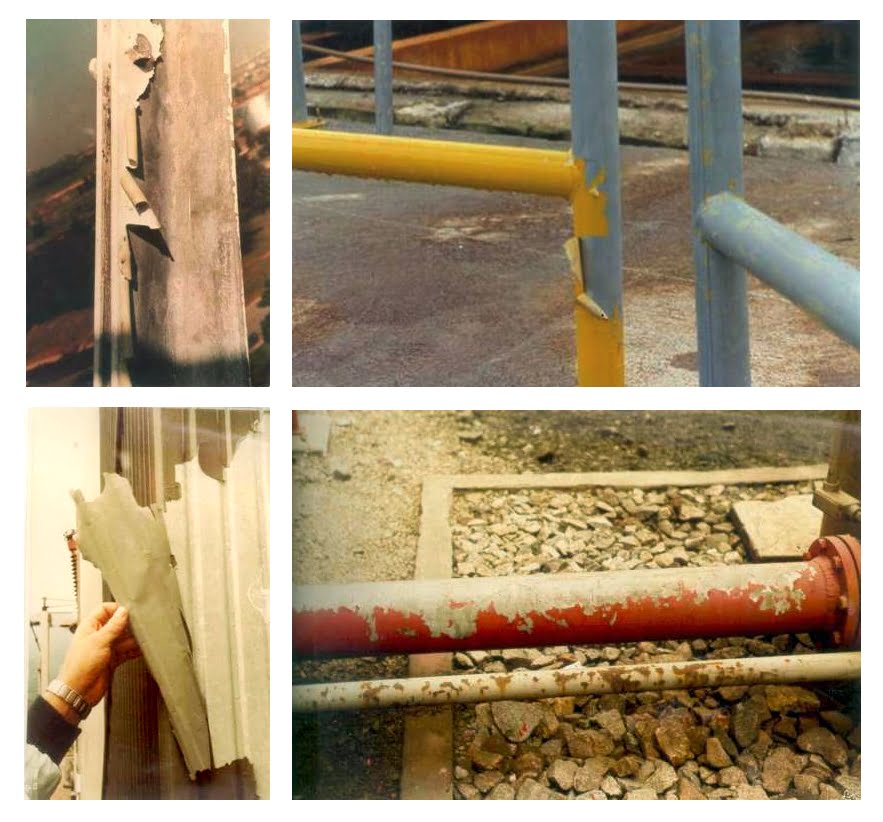

For the electric power and sanitation sectors, the Lab performed a comprehensive field survey identifying the corrosion problems of these sectors and, on the basis of this survey, settled the best options of corrosion protection methods for equipment and structures by means of metallic and organic coatings. For the electricity sector, the Lab prepared a Handbook about corrosion and protection and for the sanitation sector prepared a set of standards and specifications. The Lab also performed studies related to stress corrosion cracking of metallic materials used in hydropower plants.

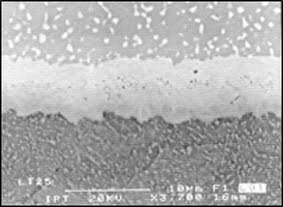

For the oil and gas sector, the Lab has been working intensely in all exploiting, storing, transporting and refining steps, as for example: detection and mitigation of alternating current interferences in buried pipelines; identification of alternative coatings for cadmium in offshore environments; electroless nickel plating specifications; effect of lightening in pipelines; study of corrosivity of biofuels (ethanol and biodiesel); study of corrosivity of concentrated sulfuric acid; internal corrosion of pipeline monitoring; external corrosion of pipelines and inhibitor and H2S scavenger selection.