For an adequate selection and specification of a metal or a metallic coating, a thorough characterization and evaluation of its performance, in a desired environment, is an important issue.

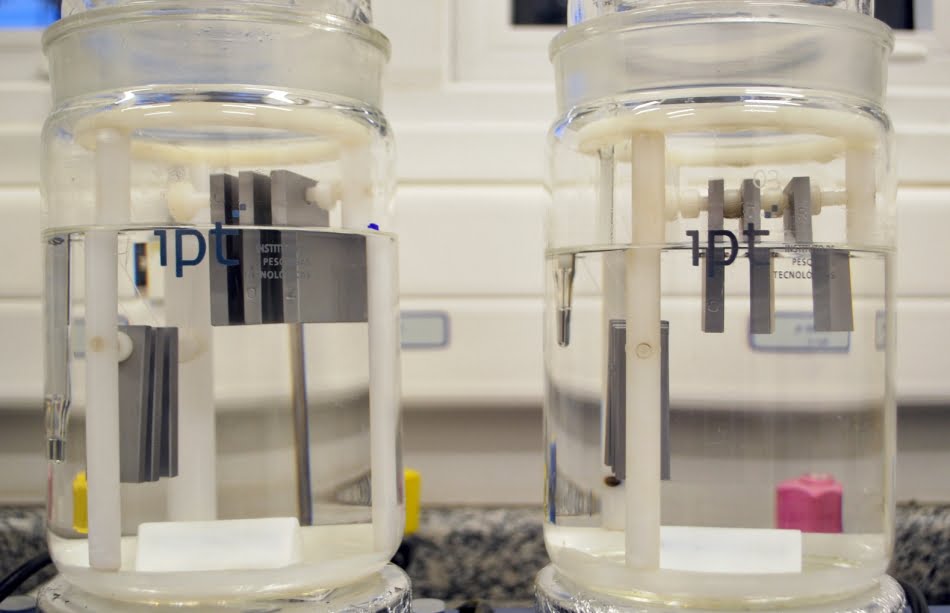

The Laboratory for Corrosion and Protection of IPT conducts tests and analyses in metals, metallic alloys and metallic coatings (zinc, aluminum, copper, brass and cadmium, among others) in order to characterize them and to evaluate their performance against corrosion in specific environments. With an experienced technical staff and a modern and well-equipped Laboratory IPT performs the great majority of standardized tests and develops specific tests, according to customer needs. Among them, there are:

- Accelerated corrosion test – acetic acid salt spray

- Accelerated corrosion test – copper accelerated acetic acid salt spray (cass)

- Accelerated corrosion test – hydrogen chloride atmosphere

- Accelerated corrosion test – kesternich test (humid sulfur dioxide test)

- Accelerated corrosion test – salt spray (fog) test

- Adhesion test for metallic coatings including zinc: flattening, bending, winding, hammer, thermal shock, pull-off, among others

- Atmospheric (natural) corrosion tests (including industrial facility internal atmospheres)

- Cathodic protection – pipe/soil potential determination, soil resistivity, oxidation reduction potential determination, anode efficiency determination

- Corrosivity of motor cooling additives

- Electrochemical tests (cyclic polarization, voltammetry, impedance spectroscopy, kelvin probe scanning)

- Film forming rust preventives – characterizartion and performance evaluation

- Intergranular corrosion – verification of the susceptibility for of stainless steels

- Mass per unit area – anodic coatings on aluminum; zinc coatings; tin coatings

- Offshore corrosion tests (floating laboratory named isabel)

- Pitting and crevice corrosion – verification of the susceptibility for stainless steel

- Residual stresses: verification of the presence in stainless steels, in copper and copper alloys, among others.

- Sealing of anodic coating on aluminum – mass loss method; dye absorption method

- Sem/feg/eds/raman/afm – microscopic tests and analyses

- Stress corrosion cracking – verification of the susceptibility for carbon steels, stainless steels, copper alloys, among others

- Thickness – measurement by magnetic method, eddy current method, x-ray spectroscopy method, coulomertric method, gravimetric method

- Uniformity verification of zinc coating

For such tests, IPT has modern equipment, such as potentiostat, accelerated test, scanning electron microscope (SEM) and field emission scanning electron microscope (FEG), among others.